YOUR COMPLETE GUIDE TO CUSTOMIZED AND BESPOKE METAL ELECTRONIC ENCLOSURES

Bespoke vs Customized Metal Enclosures

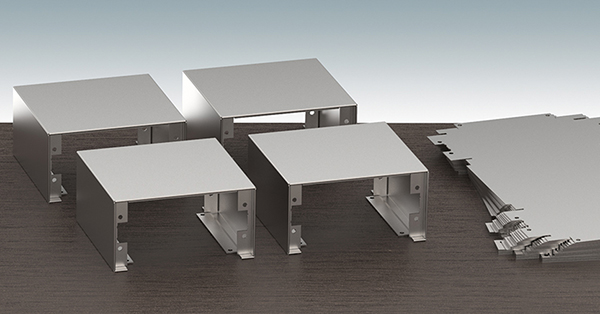

Virtually every METCASE enclosure is customized in some way before it is shipped to the customer.

Fabricated metal enclosures are much easier and more cost-effective to customize than plastic housings because the tooling costs are much lower. So you can specify customized metal cases in much smaller batches.

This is a significant advantage for designers of specialized electronic instrumentation manufactured in much lower volumes. It can also help to reduce costs and speed up production for companies manufacturing electronics products in much larger unit quantities.

You’ll note that so far we’ve used the term ‘customized’ – rather than ‘custom’. It’s important to differentiate between the two (because it can save you a lot of time and money):

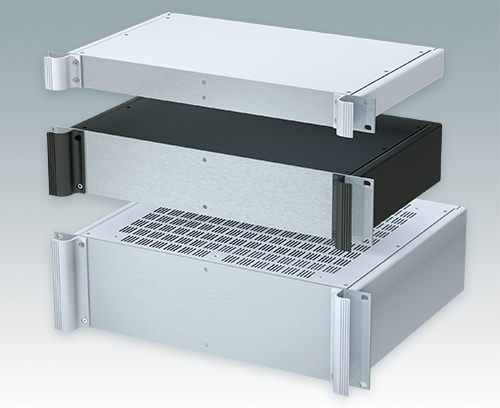

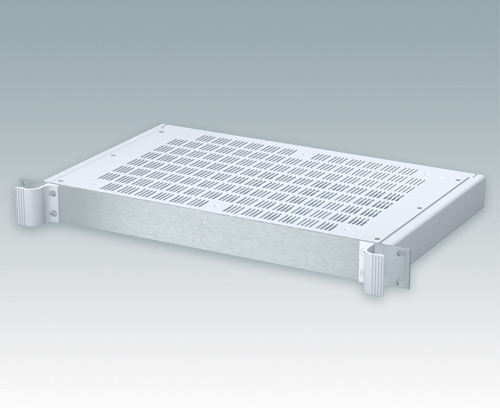

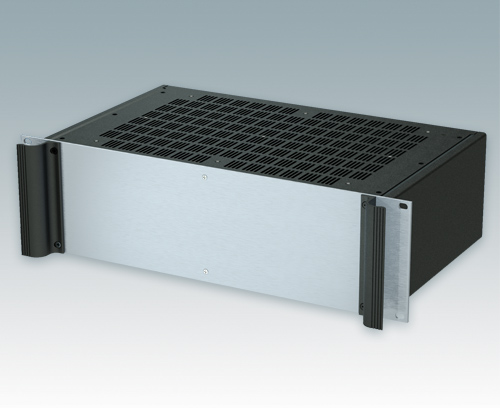

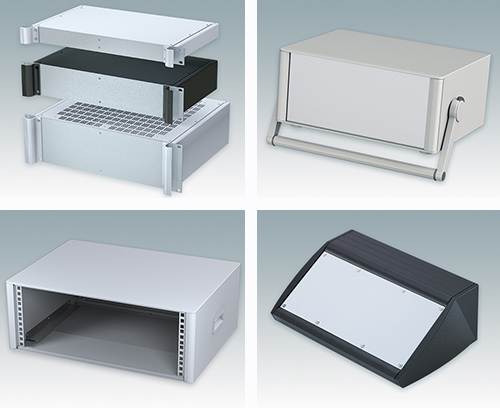

- Customized enclosures are standard 19” rack cases or instrument housings that have been modified to suit your requirements. Customizing an existing design is almost always quicker, easier and more cost-effective than specifying a custom/bespoke enclosure.

Both types of enclosure – customized and custom – will be shipped to you fully finished and ‘production line ready’. These ‘out of the box’ enclosures are ready for your electronics to be installed – speeding up your production, boosting your output and increasing efficiencies.

And to make the process even simpler, the METCASE website makes it very easy to specify your customization requirements. You can add the various customizing processes to your basket/list as if they were products.

GETTING STARTED WITH CUSTOMIZED ENCLOSURES

VIEW THE RANGE, WATCH THE VIDEOS, REGISTER FOR 3D MODELS

We recommend that you start by looking at our range of standard enclosures – all of which can be modified to suit your specific requirements. Each model page has a video tab. Click it to see exploded views of your preferred enclosure.

Once you’ve found the standard model that best suits your requirements, the next move is to download the 2D drawings and/or 3D models (you will need to register for the 3D models). You’ll find details of how to do this here. The 2D drawings are available in two formats: dwg and dxf. The 3D models are available in three formats: sat, stp and x_t. With these you can visualize how your electronic components will look in your customized enclosure.

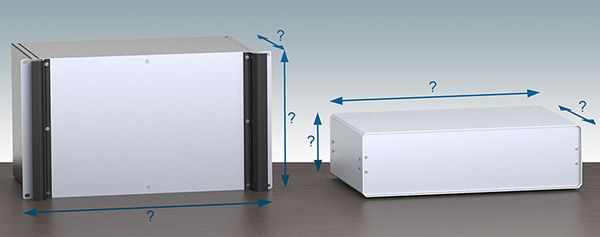

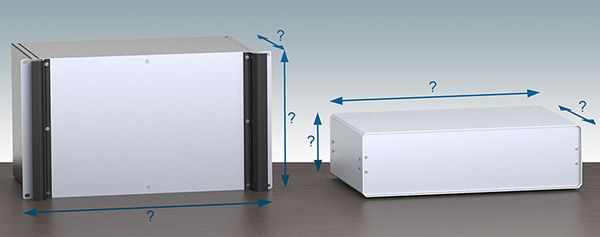

SPECIFYING METCASE ENCLOSURES IN CUSTOM SIZES

All METCASE standard enclosures can be specified in custom sizes to accommodate your PCBs and other components:

- custom widths are available for all models

- custom lengths/depths are available for all models except UNIDESK sloping front terminal enclosures

- custom heights are available for COMBIMET 19” rack cases, TECHNOMET 19” mini-racks, and for all instrument enclosures except MINIMET and UNIDESK.

Custom-sized housings generally cost more than standard enclosures but quantity generates economies of scale – even for comparatively small orders. It does not take much to create a significant saving per unit because new technology has reduced set-up times.

The extra materials required for larger enclosures can have some effect on the price but the main factor is quantity. Some very large custom-sized enclosures may need added strengthening – resulting in extra design work – but this is rare.

The usual minimum order for a custom-sized enclosure is 10 units.

Specifying The Right Materials

SHEET ALUMINUM, ZINTEC, CARBON STEEL OR EVEN PLASTIC

METCASE manufactures all 19-inch rack cases and instrument enclosures from fabricated aluminum as standard. We use two grades:

- 1050 aluminum – which offers excellent corrosion resistance and folds well. We can bend this medium-strength metal to a tight radius without breaking it. This grade also machines well.

- 5251 aluminum – a medium-strength alloy with good ductility and formability. It has a high corrosion resistance, especially in marine environments. Like 1050, this grade is also easy to machine but is less easy to bend to a tight radius. Bending in the direction of the grain overcomes this issue.

Other metals stocked for custom-specified housings include galvanized steel, Zintec (zinc-plated steel) and cold-rolled CR4 carbon steel:

- Cold-rolled CR4 steel is stronger than aluminum and also heavier. CR4 is more prone to corrosion than aluminum (despite the low carbon content of this grade of steel).

- Zintec – also known as Electro Zinc Steel – is a versatile steel plate that has been electrolytically coated with zinc to help protect it against corrosion. So it is much more durable than cold-rolled steel when used in wet environments. Zintec is excellent to machine but – being a mild steel – it is not as tough as aluminum. This is one reason we use aluminum as standard for our enclosures.

- Galvanized steel – like Zintec – has zinc added to help protect it against corrosion. The steel is galvanized by dipping it into a bath of molten zinc (whereas Zintec uses electrolysis). Aluminum offers superior performance and is lighter.

We manufacture most of our enclosures from 1.5 mm thick aluminum. But the front panels are often 2 mm thick for extra strength. Front panels for 19” rack cases can be as thick as 3 mm to provide the extra support needed for mounting them. For more information about metal thickness, please see the 3D models and 2D CAD data for each enclosure. For the record, the usual bend radius is 0.012" – giving your enclosures good, smart edges.

ABS plastic sheet is used for internal brackets and mounting plates when electrical contact is not wanted. ABS is a tough and dependable plastic: the acrylonitrile provides chemical and thermal stability, while the butadiene adds toughness and strength. ABS has a high tensile strength, is very resistant to physical impacts and chemical corrosion – and it can be recycled. It is vulnerable to weakening by UV light but this is not an issue when it’s used inside an enclosure.

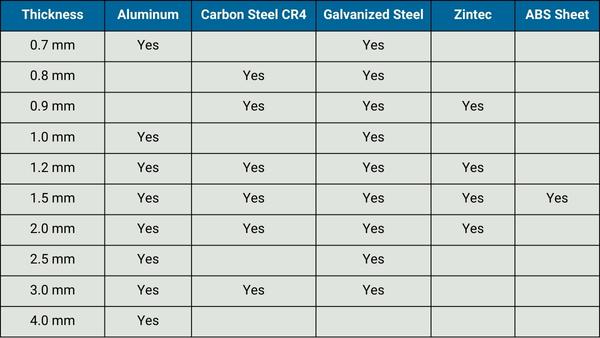

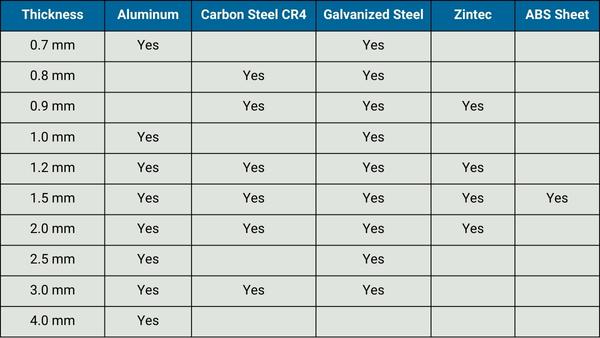

STANDARD STOCKED SHEET MATERIALS

Here is a list of the sheet metals we usually keep in stock. Please confirm availability with us when you are ready to specify your enclosure components.

For more information about sheet metals, view our CNC Punching and Folding page. Scroll down to the list of products/services. You’ll find six sheet metals at the top of the list. Click on the ‘i’ information tab on each metal to find out more. Then add your chosen metal to your basket/list.

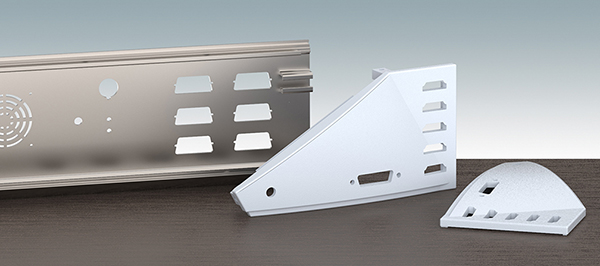

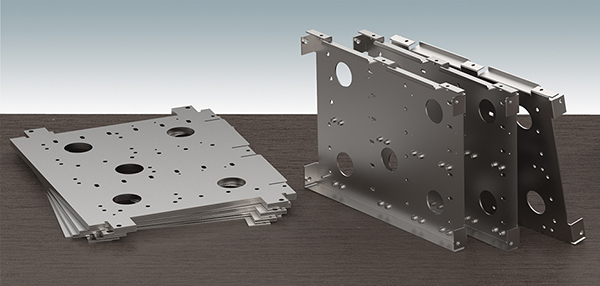

CNC Punching – Specifying Holes/Cutouts

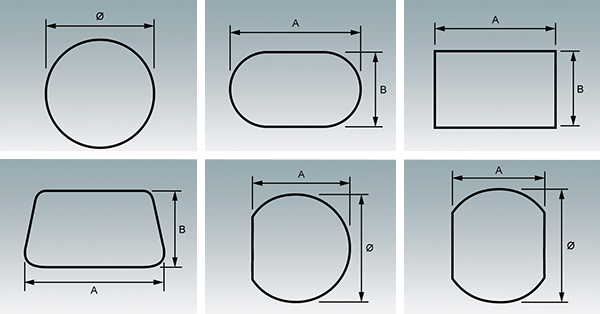

ROUND, OBROUND, RECTANGULAR, SQUARE, HDMI, D-SUB AND MUCH MORE

Your enclosures will need apertures for switches, potentiometer spindles, lights, connectors, extra ventilation, a power supply and so on. We can CNC punch/machine them for you quickly and easily.

With CNC punching, the holes and cutouts are punched into the flat sheet blanks before they are formed into the enclosure parts: tops, bases, rear and front panels. This reduces the cost of adding the holes and cutouts as the processing is carried out at the same time as basic enclosure parts are produced.

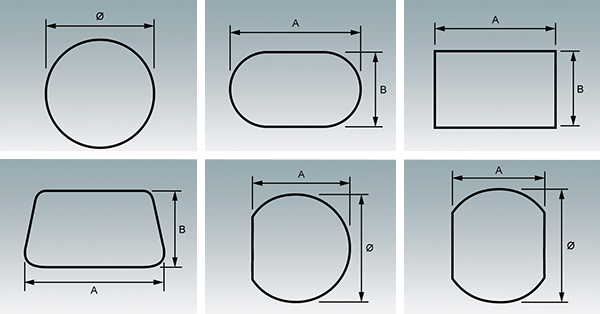

STANDARD CUTOUT EXAMPLES

There are 11 different standard cutouts to choose from:

- Round – from 0.039" to 3.340" diameter

- Obround – from 0.137" x 0.062" to 2.952" x 1.181"

- Rectangular – from 0.118" x 0.039" to 4.202" x 1.427"

- Square – from 0.078" to 1.968"

- HDMI – 0.234" x 0.606" and 0.267" x 0.641"

- D-Sub – from 0.771" x 0.413" to 0.450" x 1.180"

- SD – from 0.194" x 0.173" to 2.204" x 2.086"

- DD – from 0.157" x 0.112" to 1.378" x 1.189"

- Keyway – from 0.248" to 0.629" (diameter)

- Ventilation louvre – 1.948" x 0.590" and 3.070" x 0.618"

- Corner radius – from 0.098" to 0.590".

View the full list of dimensions for each of the 11 cutouts here. Click the ‘i’ button on each item listed for further information about:

- aluminum, galvanized mild steel, CR4 and Zintec sheet metal – material grades, stocked sizes, thicknesses, available finishes

- cutout ranges, diameters, dimensions

- corner radii.

Need something different? We can source custom-sized punches. And we can machine fully bespoke cutouts (such as company logos) – just ask us.

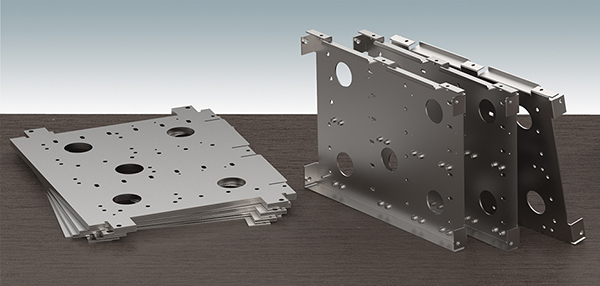

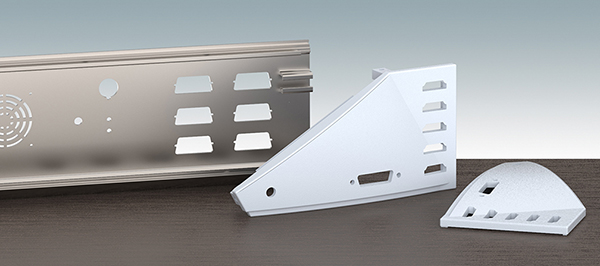

CNC Machining – Specifying Holes/Cutouts

MILLING, DRILLING AND TAPPING

All METCASE enclosures can be machined with apertures and slots for mounting connectors, switches, displays, fan units and other components. Holes can be tapped with metric or standard threads.

We will work to your drawings and specifications. State-of-the-art CNC machines at our factory guarantee uniformity and a high-quality finish for all your milling, drilling and tapping requirements. The machining tolerances are:

- +/- 0.00039" for cutouts, recessed areas, holes of lengths up to 1.181"

- +/- 0.0059" for lengths up to 4.724"

- minimum corner radius, 0.039".

It’s easy to add CNC machining to your RFQ quickly and easily because this customizing service – like all the others – has its own product number (M0000420).

Specifying Custom Front Panels

CNC MACHINED, PRINTED/ENGRAVED, FULLY FINISHED

Custom-machined and finished front panels are available for all METCASE enclosures – ready for mounting LEDs, displays, switches, potentiometers and other components. Customization options include:

- CNC punching of holes and cutouts, drilling and tapping

- fitting inserts, studs and earth tags

- linishing of aluminum panels for a blemish-free finish, natural and color anodizing

- powder coating or wet painting (at no extra cost for ‘always in stock’ colors)

- photo-quality CMYK digital printing

- engraving of control legends for heavy-duty applications.

Click on the button below to view a range of examples then add Custom Front Panel (M0000410) as a product to your basket/list.

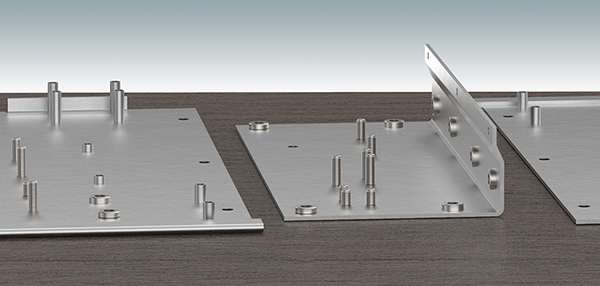

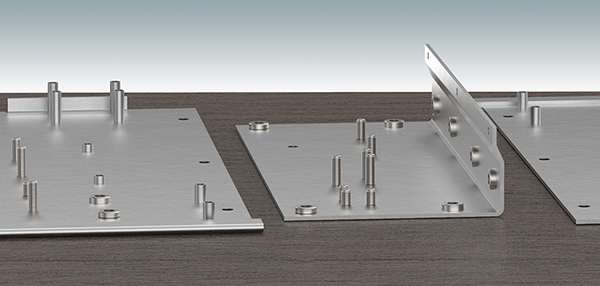

Specifying Custom Fixings And Inserts

FASTENERS, SELF-CLINCH NUTS, STUDS, STANDOFFS

Many METCASE enclosures have M4-threaded earth studs fitted as standard. Some have them on every panel. These are typically newer models such as TECHNOMET instrument enclosures, TECHNOMET 19” mini-racks and our wide range of COMBIMET 19” rack cases.

But if they don’t then adding studs and other fixings to your enclosures as a custom requirement is very simple. Just view the range of fixings and inserts then add them as products to your basket/list:

- Flush-head fixing studs – the embedded head is flush with the face of the panel (which is drilled to accept the stud). The head – though flush – will leave a visible circular witness on the outside of the panel. (External thread: M2, M2.5, M3, M3.5, M4, M5, M6).

- Through standoffs – you can see through them; the head is open. (Internal thread: M2, M2.5, M3, M4, M5).

- Blind standoffs – you can’t see through them; the head is closed. (Internal thread: M2, M2.5, M3, M4, M5).

- Concealed-head standoffs – no witness, ideal for front panels, panel thickness 0.062"-0.094". (Internal thread: M3, M4).

- PCB standoffs – the pre-drilled PCB clips on to the secured standoff.

- Self-clinch nuts – internal thread: M2, M2.5, M3, M3.5, M4, M5, M6, M8, M10.

- Right-angle panel nuts – internal thread: M3, M4.

- Cable tie mounts – push fitted into rectangular cutouts, choose from three sizes.

Click on the button below to view the range of fixings and inserts. By clicking the ‘i’ button on each type of fixing, you’ll see details of:

- stud lengths

- mounting hole diameters (Ø)

- circuit board hole diameters (Ø) for PCB standoffs

- fixing hole heights for right-angle panel nuts

- cable tie aperture sizes for cable tie mounts.

Finishing: Powder Coating vs Wet Painting

What’s the difference? Powder coating is a dry thermoplastic that is applied electrostatically and bonded to the enclosure sections in an oven. Curing the powder under heat allows it to liquify and flow, forming a skin that is tougher than normal paint. Powder coating also offers other advantages:

- Finish quality – the coating is thicker. You can choose from smooth, fine and heavy textures. Also, powder paint is less susceptible to cracking under movement.

- Cost savings – powder is a solid so any over-spray can be reclaimed. This makes it a better way of painting; the transfer efficiency ratio is higher.

- Safety/environmental benefits – powder paint contains no solvents or volatile organic compounds. It’s much safer to handle because it’s solid and inert.

We do all our own powder coating in-house to ensure optimum quality every time. Choose from a wide range of colors, gloss levels and textures. Important note: powder coating will add a thickness so please allow for this when specifying cutouts. Get expert technical advice from our engineers on the typical tolerances involved.

Specifying Custom Colors

You can specify your enclosures in any color(s) you like (matched to RAL or Pantone). There are some clever and very cost-effective ways of doing this…

Download the list of ‘always in stock’ colors here (PDF) – you’ll pay no extra cost for these. Lots of choice, no premium to pay and you can have the color you want immediately because we always have plenty of it ready for you.

And that’s not the only way to keep costs down. You don’t have to custom-color the entire enclosure. Quite the opposite – often all it takes is a different colored front panel or a discreet highlight on a bezel/trim to give your enclosure its unique visual identity.

This ‘less is more’ approach produces great looking enclosures…and all the while you’re benefiting from low finishing costs and sensible lead times. Click here to see some examples of what can be achieved with this smart approach. Here are some examples of what can be achieved with this smart approach:

Specifying Other Finishes

Other finishes include:

- nickel-loaded RFI/EMI shielding lacquers for plastic parts

- linishing of aluminum panels for a blemish-free finish

- natural and color anodizing of aluminum panels

- Iridite NCP conductive/anti-corrosion finish for aluminum panels

- zinc and clear passivate for CR4 steel panels.

Iridite NCP is a chrome-free passivation process that is best suited to internal components which will not be seen. We don’t recommend it for visible surfaces.

It offers excellent corrosion resistance, making it a good base layer for powder coating and painting. Iridite NCP withstands oven temperatures of up to 350°C and – unlike other chromate conversions – needs no oven curing time. It offers a good level of electrical conductivity.

Applying Iridite NCP does not involve using an electrical current. It is simply a matter of dipping the enclosure sections or components in an acidic solution: the coating is formed through a chemical reaction with the metal.

Iridite NCP is an effective and safer alternative to traditional hexavalent chromates. It produces a trivalent chromium conversion coating on both wrought and cast aluminum surfaces, providing an iridescent to clear surface finish. Iridite NCP is free of cadmium, lead, mercury and polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE) compounds. So it will meet standards such as ELV, RoHS and WEEE.

Matt anodizing is the standard finish on all our front panels. It is also optional on rear panels and other made-to-order components. But we don’t recommend it for enclosure covers, side panels, tops and bases – these look better when powder coated or painted.

Pretreatment is applied to all aluminum and CR4 mild steel components before painting. This removes oils, greases and other agents used in manufacturing; it converts the metal surface to a non-metallic layer.

We pretreat all unfinished internal parts, giving the metal a brown/gold surface coloration. Panels which are due to be anodized are not pretreated.

Zinc and clear passivate is used in stage two of the zinc-plating process. Adding this chemical passivate to the zinc-plated metal enhances the corrosion resistance and adds color.

Like other customizing processes, each color or finish has its own product number so it’s easy to add to your quote request. This makes specifying customization faster and easier for you. It also enables us to respond to your RFQ more quickly.

Bare Metal Finishes

Not every part requires finishing. You may wish to specify ‘no finish’ for parts that will not be seen. In this instance, we will deburr the part (possibly leaving it with small swirls). Other bare metal finishes include:

- linishing the deburred part to give it a specific linear grain

- tumbling the part in an abrasive medium to create a non-directional finish (creating a similar finish to frosted glass).

Specifying Photo-Quality Digital Printing

PRINTING LEGENDS, LOGOS, GRAPHICS AND PHOTOS

Digital printing is not only better – it’s also more cost-effective. This is because the set-up costs are much lower than those needed for traditional printing methods. So you can specify stunning quality graphics on even low-volume production runs.

Get outstanding print quality (full CMYK) up to 1,800 x 1,800 dpi on areas as large as 23.62" x 16.53" (600 x 420 mm – A2). We can also print barcodes and QR codes. Awkward surfaces need not be a problem: we can print directly on to products up to 5.90" high.

Production times are much faster too because:

- our flatbed printers can print color and white simultaneously

- jig templates enable us to print multiple front/rear panels or cases in each cycle.

These efficiencies also help to keep costs down.

Click on the button below to find out more here about digital printing on your customized metal enclosures. This page contains useful information about what we will need from you (preferred and other file formats). Need help? Contact our engineers for more information about digital printing.

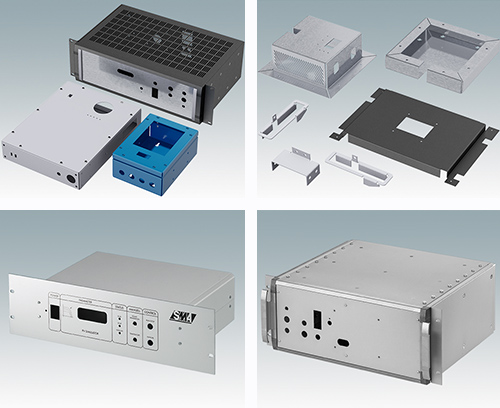

Specifying Fully Bespoke Metal Enclosures

Despite all the design and efficiency benefits offered by customized electronic enclosures, some applications require fully bespoke housings. For a fee, our special projects team can design and manufacture a prototype that will solve your project challenges.

This prototyping service is available when you specify a minimum order of 10 pieces for production. Find out more here about specifying prototype metal enclosures for electronics.

As we mentioned earlier, specifying a bespoke metal electronic doesn’t have to be more expensive than customizing a standard model. Simple bespoke enclosures can be highly cost-effective. Get inspiration here.

METCASE Compliances And Certifications

METCASE is committed to complying with the REACH, RoHS and WEEE directives. We are also certified ISO 9001:2015. Find out more here:

Further Reading

Get Expert Help. How To…

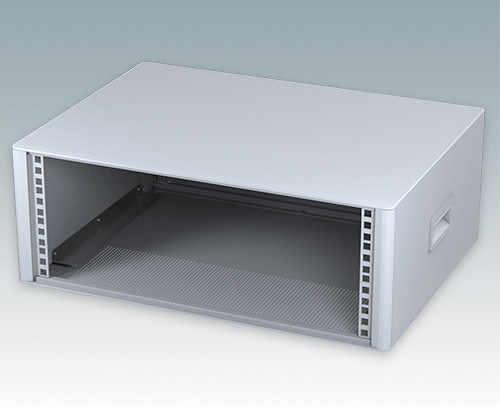

19" Enclosures

19" Enclosures

Metal Enclosures Modern metal enclosures for OEM electronics equipment

Metal Enclosures Modern metal enclosures for OEM electronics equipment

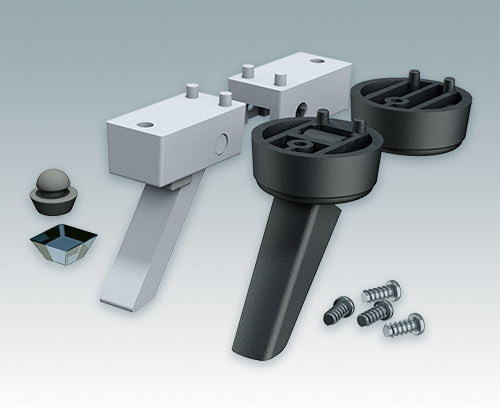

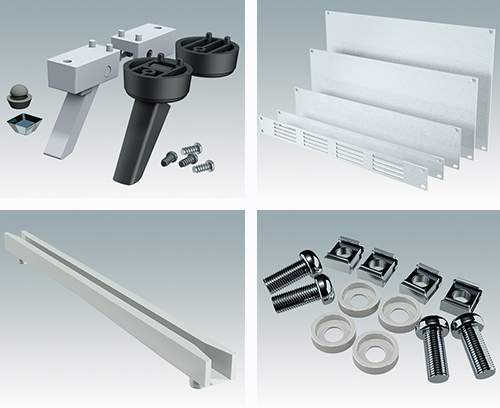

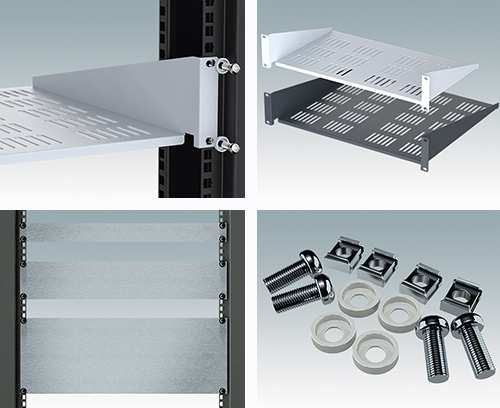

Accessories for Enclosures Extensive range of universal accessories

Accessories for Enclosures Extensive range of universal accessories Accessories for 19" Racks Universal accessories for 19" equipment

Accessories for 19" Racks Universal accessories for 19" equipment

Modifications & Finishing All the customizing services you need

Modifications & Finishing All the customizing services you need Bespoke Enclosures Bespoke metal enclosures and sheet metal parts

Bespoke Enclosures Bespoke metal enclosures and sheet metal parts

News

News Press Releases

Press Releases Blog

Blog

Specifying Customized Enclosures

Specifying Customized Enclosures ROHS / WEEE Directives

ROHS / WEEE Directives Discontinued Products

Discontinued Products

General Inquiries Form

General Inquiries Form How To Find Us

How To Find Us Worldwide Sales Network

Worldwide Sales Network